Isostatic Refractories

AksTech is representing a worldwide well known company in Isostatic Refractory Technology for Tundish flow protection and control applications.

Isostatic pressing of carbon bonded refractory oxides is a tecnology allowing complex designs in steelmaking refractories for some special applications. These special applications are mostly classified in two main groups, such as protection of the stream, and controlling the liquid steel flow from tundish to mold. These products are widely used for quality steels by slab and alloy steelmakers.

Product Range:

B: Ladle Shroud (LS)

C: Stopper Rod (SR)

H: Tundish Nozzle (TN)

D: Tundish Shroud (TS)

I: Submerged Nozzle (SN)

Ladle Shroud (LS), is used for the protection of the steel stream from ladle to tundish. The connection of LS is done to the collector nozzle of the Ladle Slide Gate with the help of a manipulator. The LS has a submerged entry to the steel bath in theTundish. Primarily, LS application will prevent the re-oxidation of the steel, reduce the Nitrogen pickup, improve steel cleanliness and create a safer environment by eliminating splashing. There are also some secondary benefits, such as less consumption of the tundish covering compound, less tundish heat loss and less radiation from Tundish to Ladle.

Stopper Rod (SR), is used to control the steel flow from the Tundish to Mold. The SR fixed into the Tundish on the casting strand with the help of a steel rod, fixed into the SR, and connected to manipulator arm which can control the SR with upward-downward movements. The SR control mechanisms can be manual-controlled or automatic-driven. The SR sits on the seat area of either a Tundish Nozzle (TN) or a Submerged Nozzle (SN) which are both casting channels out from the tundish. Under the TN a type Tundish Shroud (TS) has to be used. The TN to TS connection can be done with various possible methods, such as either direct refractory conical connection or with the help of a exchange mechanism. Depending on the connection method, TS may have different sizes and connections from the TN to the mold. Several models are designed according to customer needs. The SN is long one- piece solution to allow directly the submerged flow into the mold from the Tundish.

Please contact to our specialists for investigating suitable design and quality for your applications.

Slide Gate Refractories

AksTech is representing a worldwide well known company in Refractory Technology for Tundish flow protection and control applications such as Slide Gate Refractories consisting of Inner Nozzles, Plates and Collector (or Outer) Nozzles.

A : Ladle Slide Gate Refractories

E : Tundish Slide Gate Refractories

Please contact to our specialists for investigating suitable qualities for your applications.

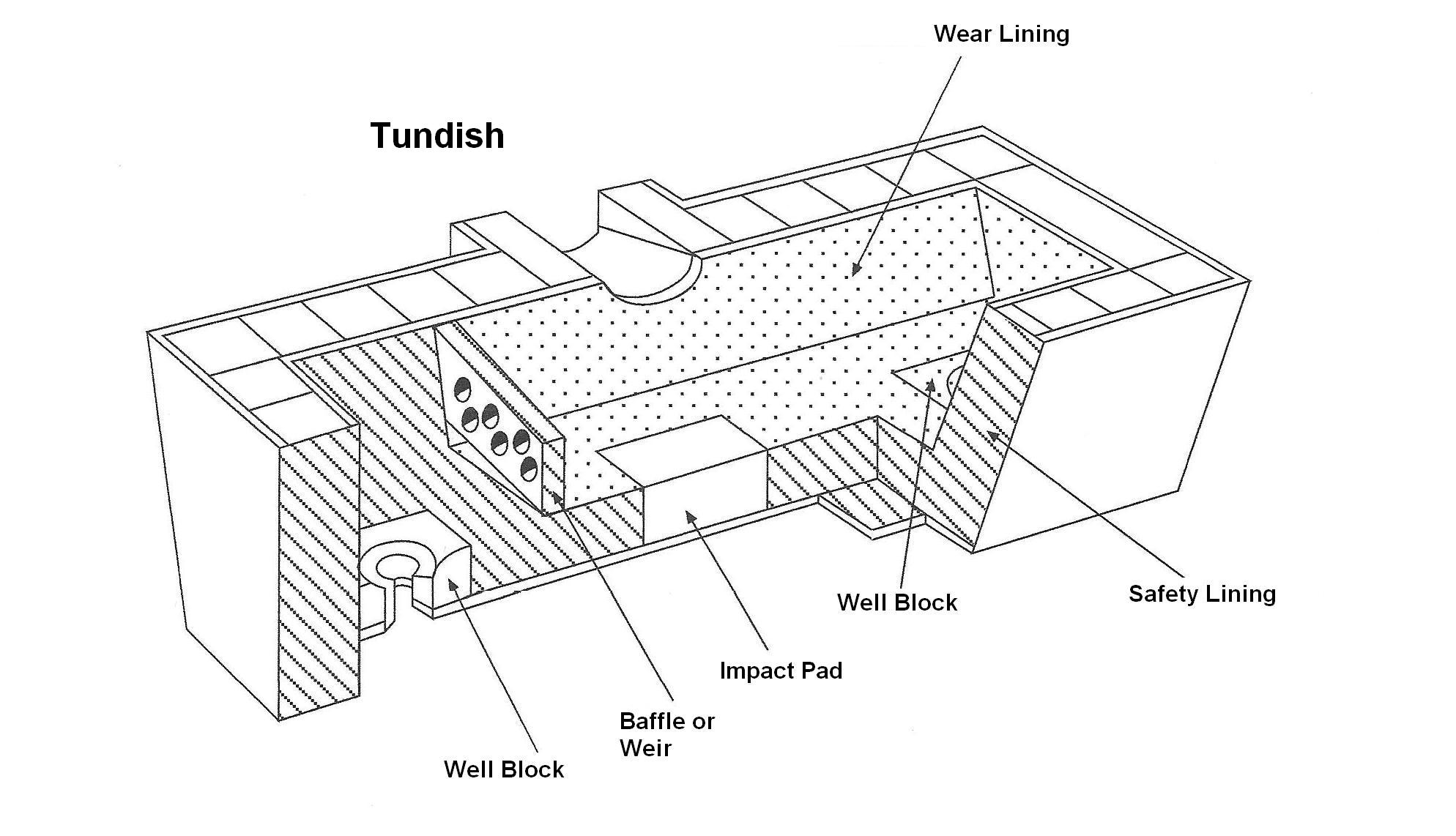

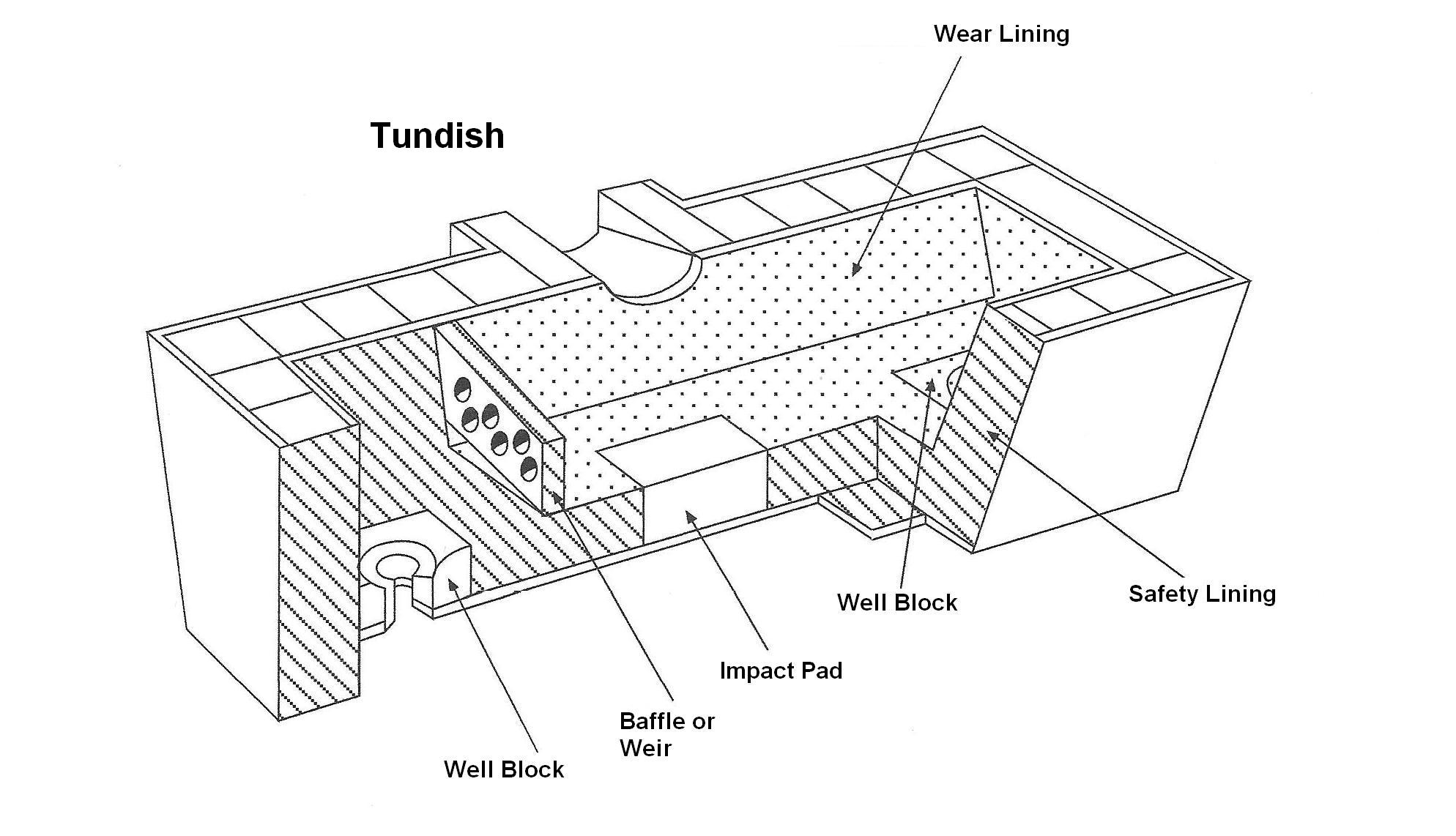

Tundish Precast Shapes

AksTech is representing a worldwide well known company in Refractory Technology for Tundish flow protection and control applications including tundish precast shapes.

Please contact to our specialists for investigating suitable qualities for your applications.

Zirconia Nozzles

AksTech is representing a worldwide well known company in Refractory Technology for Tundish flow control applications such as Zirconia Nozzles.

Please contact to our specialists for investigating suitable qualities for your applications.

Tundish Monolithic Refractories

AksiTech has its own technology for Tundish monolithic lining products and applications.

Wear Lining: Tundish Spray Coating

Tech-Spray series, sprayable coating material is a high performing tundish wear lining. Quick and clean deskulling property is the key success function of TechSpray products. It is designed to adhere to steel skull which allows the removal safe and simple procedure.

Due to lower labor costs, easy and efficient installation, the sprayable tundish coating has gained worldwide acceptance in many billet, bloom and slab casting facilities. It can be sprayed on any refractory surface up to 80°C, which enables the steelmaker to utilize residual heat in the tundish helping to cure the lining. With zero rebound it is sprayable to any tundish regardless of geometry. The material consumption can be optimized by customer himself by placing less material in low erosion zones.

Product Range: Tech-Spray 60/65/70/75/80/85/90

Wear Lining: Tundish Dry Vibratable

Tech-Vibe series, moldable water-free coating material is a high performing tundish wear lining. It is applied by filling between the permanent layer of tundish and the steel former. The former is removed by crane after setting of material in 90 minutes. The material is originally designed to work as heat-set before removal. Based on customer requirements, material with cold-set property could be also offered. The original material could be used in both cold and hot tundish preheating practices. Tech-Vibe series products are suitable for long tundish sequences over 24 hours. Quick and clean deskulling property is the key success function of Tech-Vibe products. It is designed to adhere to steel skull which allows the removal safe and simple procedure.

Product Range: Tech-Vibe 75/80/85

Tundish Ramming and Sealing Mixes

Tech-Ram and Tech-Seal series, ramming and sealing mortar products are designed to work in the tundishes for multi-purpose applications. Based on customer requirements, either Silica, Magnesia or Alumina based products are recommended.

Product Range: Tech-Ram S/M/A and Tech-Seal S/M/A

Safety Lining: Tundish Castable Masses

Tech-Cast series, monolithic castable material is a high performing tundish safety lining. The material is applied as casting of the premixed wet material between the tundish insulation layer and the tundish mold. The material is air-setting and the tundish goes under drying regime after the removal of the mold. It is designed to resist against the diffusion of the steel skull which allows the removal safe and simple procedure of the wear lining.

Product Range: Tech-Cast 80/85

Please contact to our specialists for investigating suitable qualities for your applications.